CK32-6双主轴车铣复合数控车床,紧密追踪当今数控机床领域前沿技术,不断

研发和生产符合用户要求的高精度、高效率、高可靠性的机床产品,被广泛应用于

通讯、5G产品、家电、医疗器械、汽车、水暖、微型轴、光学仪器、

接插件、钟表、眼镜及各种五金配件等行业,高性价比的产品是各行各业批量自动

化生产的理想设备。

The CK32-6 Double Spindle Turning and Milling Compound CNC Lathe closely tracks the cutting-edge technologies in the field of CNC machine tools today. It continuously conducts research and development and manufactures machine tool products that meet users' requirements for high precision, high efficiency, and high reliability. It is widely applied in industries such as telecommunications, 5G products, household appliances, medical devices, automobiles, plumbing, miniature shafts, optical instruments, connectors, watches, glasses, and various hardware accessories. The products with high cost-effectiveness are ideal equipment for mass automated production in all walks of life.

(1)本机台床身、高刚性床身。结构设计稳定,高质量密烘整体铸铁床身,刚性

强。主轴箱等关键零部件均采用高品质的 HT300 铸件,经退火处理及时效处理消

除应力。铸件经有限元分析法计算,通过优化设计,合理的结构强度及加强肋的搭

配,提供机械之高刚性。

(1) The machine tool bed is of high rigidity. With a stable structural design, it adopts a high-quality densely baked integral cast iron bed, which has strong rigidity. Key components such as the spindle box are all made of high-quality HT300 castings, which are annealed and aged to eliminate internal stress. The castings are calculated by the finite element analysis method. Through optimized design, reasonable structural strength, and the combination of reinforcing ribs, high rigidity of the machine is provided.

- 一体成型超宽底座,提供最稳固的重荷支撑能力。

(2) The integrally formed ultra-wide base provides the most stable heavy load support capacity.

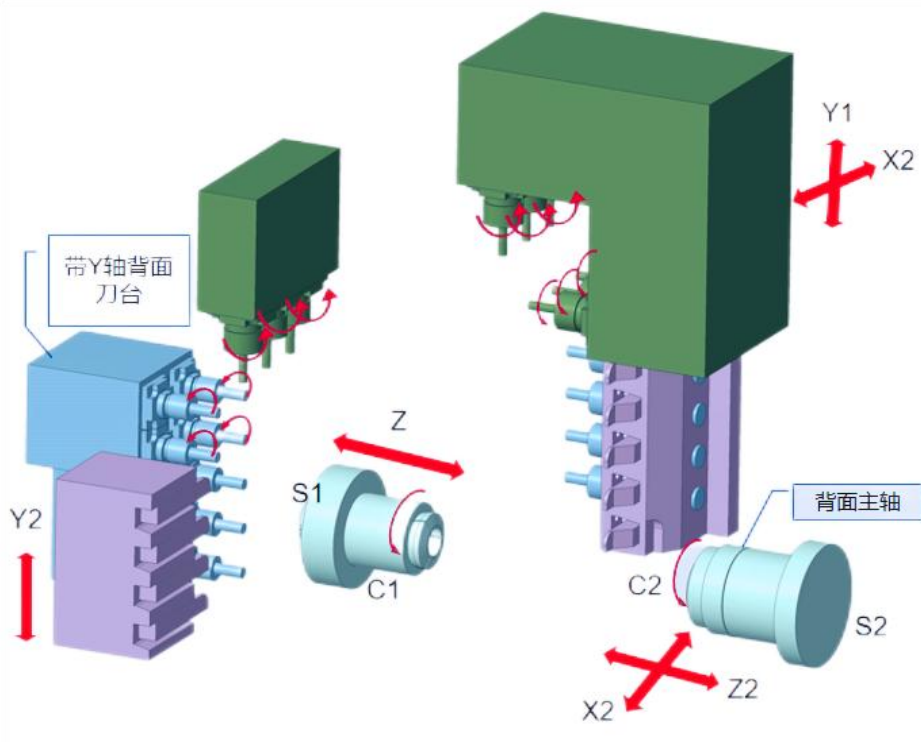

(3)高精度进给:X1、Y1、Z1、X2、Y2、Z2 轴采用高精度进口THK滚柱丝杠导

轨 高刚性结构设计;

(3) High-precision feeding: The X1, Y1, Z1, X2, Y2, and Z2 axes adopt high-precision imported THK roller screw guide rails with a high-rigidity structural design.

(4)单元式主轴结构,转动更平稳。

(4) The unitized spindle structure makes the rotation smoother.

(5)高精度主轴,采用先进的电主轴结构,副主轴轴承采用进口超高精密角接触

球轴承。标准A2-5主轴鼻端,可用于弹簧夹头或液压卡盘。

(5) The high-precision spindle adopts an advanced electro-spindle structure. The auxiliary spindle bearings use imported ultra-high-precision angular contact ball bearings. The standard A2-5 spindle nose can be used for collets or hydraulic chucks.

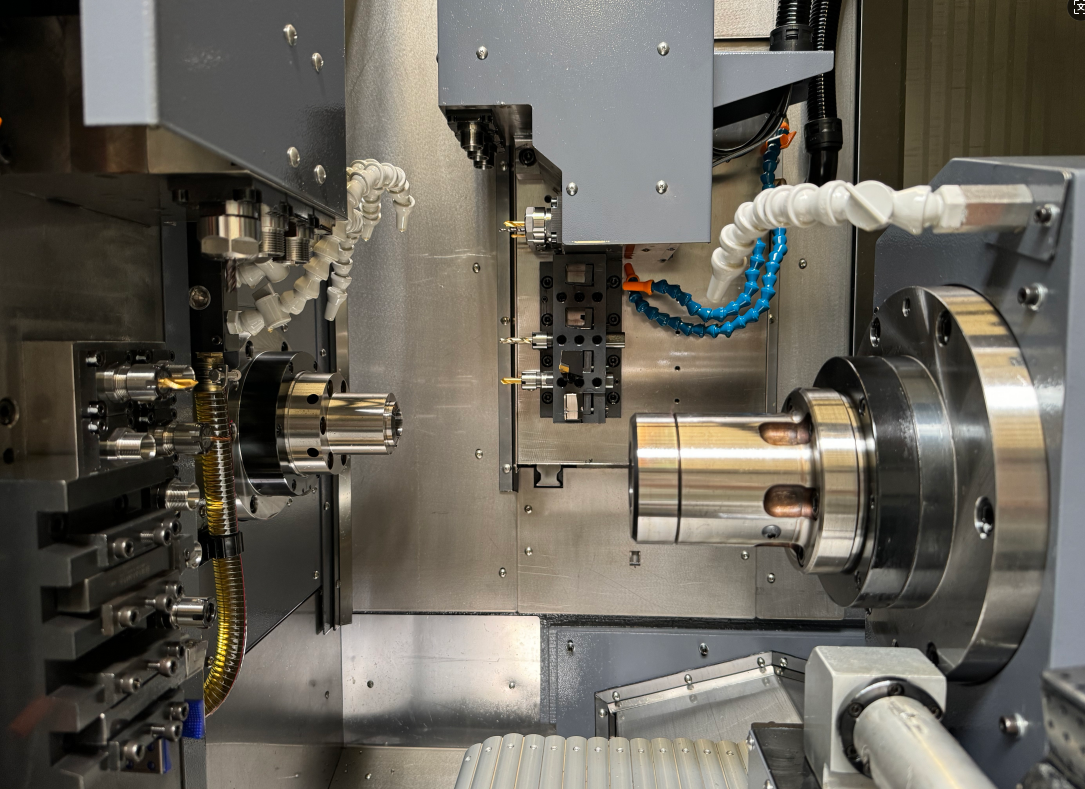

- 双立式直Y轴排刀结构,排屑顺畅,排刀更灵活。

(6) The double vertical straight Y-axis tool arrangement structure ensures smooth chip removal and more flexible tool arrangement.

(7)左右双主轴、双直Y上下式可同时独立与合作加工,利用Y轴控制,可进行复

杂形状加工;

(7) The left and right double spindles and the double vertical Y-axis up and down structure can perform independent and cooperative processing simultaneously. Controlled by the Y-axis, it can carry out complex shape processing.

(8) 绝对值伺服电机,不会因为停电产生误差。

(8) The absolute value servo motor will not generate errors due to power outages.

(9) 多选配侧/端铣:采用不同选配动力侧/端铣,采用快捷插拔更换方式,经济实

惠的方便客户选择。

(9) Multiple optional side/end milling: Different optional power side/end milling heads are available, with a quick plug-in and replacement method, which is economical and convenient for customers to choose.

- 自动化:通过配置自动送料或自动上下料结构,实现自动连续加工。

(10) Automation: By configuring an automatic feeding or automatic loading and unloading structure, automatic continuous processing can be realized.

CK20小型精密排刀式数控车床

CK20小型精密排刀式数控车床